TOFD Man Ultrasonic Weld Testing System

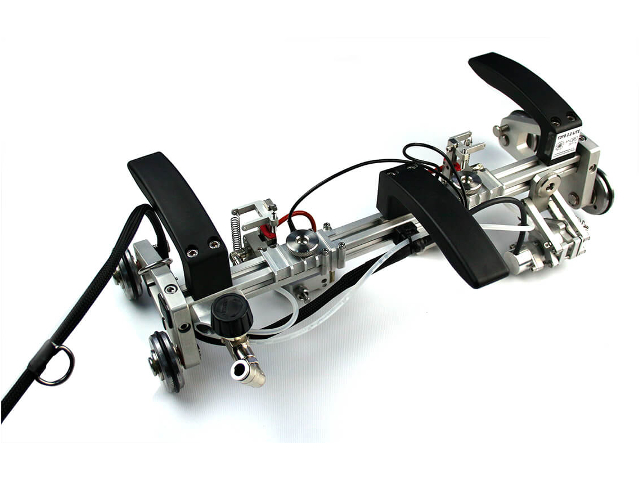

The TOFD MAN Ultrasonic Weld Testing System is an innovative solution in NDT inspection of long welds. Employing wireless technologies, the TOFD MAN overcomes the main weakness of the TOFD technique, a significant degradation of the signal-to-noise ratio, caused by the long signal cable that connects the scanner to the electronic module.

The TOFD MAN is intended for testing welds on cylindrical, spherical, and complex-shaped objects with a radius of surface curvature from 16 ft (5 m) to flatness and a wall thickness from .25 to 2 in (from 6 to 50 mm). For testing objects with a wall thickness from 2 in (50 mm) to 4 in (100 mm), appropriate probe pairs are to be installed, and scanning is to be done in several runs. For the inspection of objects exceeding 4 in (100 mm), the carrier rail of the scanner is to be changed for a longer one, with consequent installation of appropriate probes and several runs of scanning. The number of probe pairs can vary from 1 to 4. The System is capable of testing welds in any direction. The TOFD MAN System is compatible with other scanners, which can be selected depending on the application.

High Mobility and Reliable Results :

The TOFD MAN System is placed into the inspector’s utility vest, which allows easy movement, even during rope access inspection. The standard kit comes with an 8-hour rechargeable battery pack, which is easily replaceable with one hand.

Due to the Wi-Fi module, the inspector can operate the device from anywhere within the Wi-Fi range. Alternatively, all the test data saved to the internal memory are transferred to the PC at the end of the inspection, using either wireless or wired connection.

Magnetic wheels and spring-loaded probe carriers with a self-positioning system ensure transducer stability on the object surface, thus providing good acoustic coupling necessary for reliable test results. The scanner is easy to drive and does not fall from the object even when the device is turned upside down.

Being amplitude insensitive, the TOFD MAN System is not critically dependent on good acoustic coupling.

Fast and Easy Setup

The TOFD MAN features element libraries: Geometry Library, Material Library, Scanner Library, Probe Library, etc., which turn the setup process into a sequence of choices.

Mouse- and Finger-Friendly Interface

Design for Demanding Environments

The TOFD module case and the battery pack case are shockproof. In case the System falls down, the impact on its electronics is minimized due to the special design which protects the electronic module against mechanical shock.

The System has a wide operating temperature range: from –30 to +45°С.

The System is engineered to meet IP 65 specifications.

TOFD 2.2 PRO Ultrasonic Weld Testing System

The TOFD 2.2 PRO System is intended for mechanized ultrasonic butt weld inspection applying the advanced technique of Time-Of-Flight Diffraction (TOFD). Fast and reliable, the technique proves highly effective at both locating and sizing discontinuities in welds. TOFD ensures perfect accuracy of greater than ±1mm in measuring the critical through-wall size of crack-like defects in a broad range of material thickness.

The TOFD 2.2 PRO System is utilized for testing of welded joints in:

- flat objects;

- tubes of medium and large diameters – with OD no less than 12 in (300 mm) – depending on the scanner type;

- spherical and cylindrical oil and gas tanks – with OD no less than 33 ft (10 m).

Wall thickness: varying from .25 to 12 in (6 to 300 mm).

Profile types: CRC Evans, single J groove weld, single V groove weld, double V groove weld, X welds, etc.

High-Performing

The TOFD 2.2 PRO System delivers rapid full volume inspection done in a single run, providing straightaway results with data recording and imaging.

The setup time is reduced due to the element libraries: Geometry Library, Material Library, Scanner Library, Probe Library, etc.

Reliable

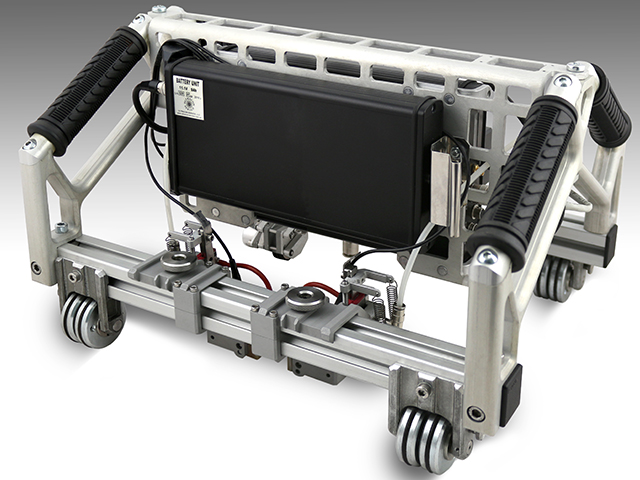

Magnetic wheels and spring loaded probe carriers with self-positioning system ensure transducer stability on the object surface which results in good coupling necessary for reliable test results.

Continuous water supply under each probe guarantees good acoustical contact.

Perfectly Suited to Demanding NDT Applications

The scanner is easy to drive and doesn’t fall from the object even when upside-down.

The TOFD 2.2 PRO System boasts drop-resistant design ensuring that at fall down, the main impact will come to the scanner structure elements saving its electronics.

The TOFD 2.2 PRO System is capable of an 8-hour continuous operation on a storage battery, and it takes only several seconds to replace the battery with one hand if necessary.

The System is IP65 rated.

User-Friendly

The wireless operating technology allows the NDT inspector with a data acquisition PC to stay anywhere within Wi-Fi range.

The TOFD 2.2 PRO System is compatible with any type of Windows-based computer: laptop, desktop, tablet, etc.

The interface is mouse- and finger-friendly.

flaw detection not depending on their orientation;

detection of planar defects and cracks not perpendicular to the inspected surface;

reproducibility of inspection;

accurate defect positioning and sizing capability;

amplitude insensitivity (acoustical coupling less critical);

a cost effective solution.