The SNK B-35 (L) is a system that can be integrated into the roll-grinding machine of any make or type to perform the inspection of the mill roll at the machining station, without transshipment. Read more …

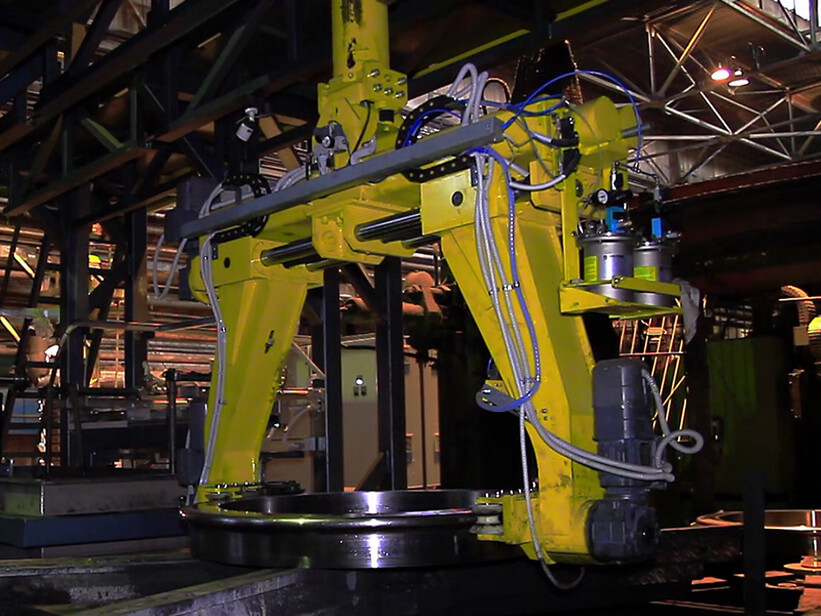

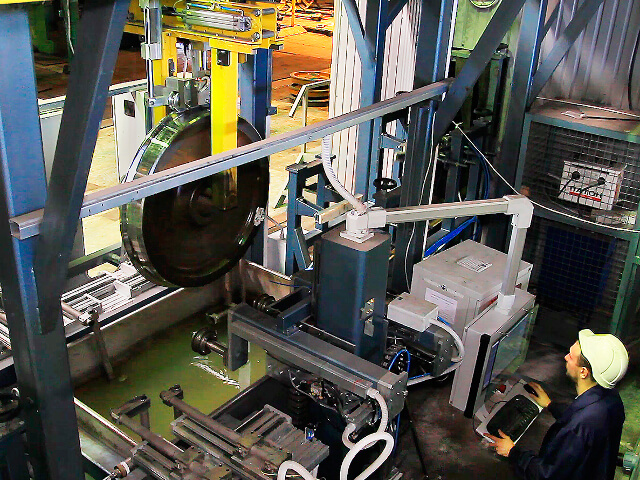

The SNK KB–13 is an integrated, high throughput automated inspection system. It is intended for ultrasonic quality control of machined and finished railway wheels and rims. Read More

The System utilizes fluorescent-magnetic technique for detecting surface defects and ultrasonic technique for detecting surface and sub-surface defects in railway wheels. Tested wheels return to the finished product acceptance stand. Read more …

The SMARTSCAN Aircraft Wheel Inspection System is a turnkey solution for automated and semi-automated testing of aircraft wheels manufactured by Messier-Bugatti, Goodrich, Honeywell, Meggitt and other world-class producers. Read More

The AXLE-4 System can be seamlessly integrated into the production process or operate as a stand-alone inspection station. The System is intended for detecting defects in the body of machined or semi-machined railway axles. Read more …