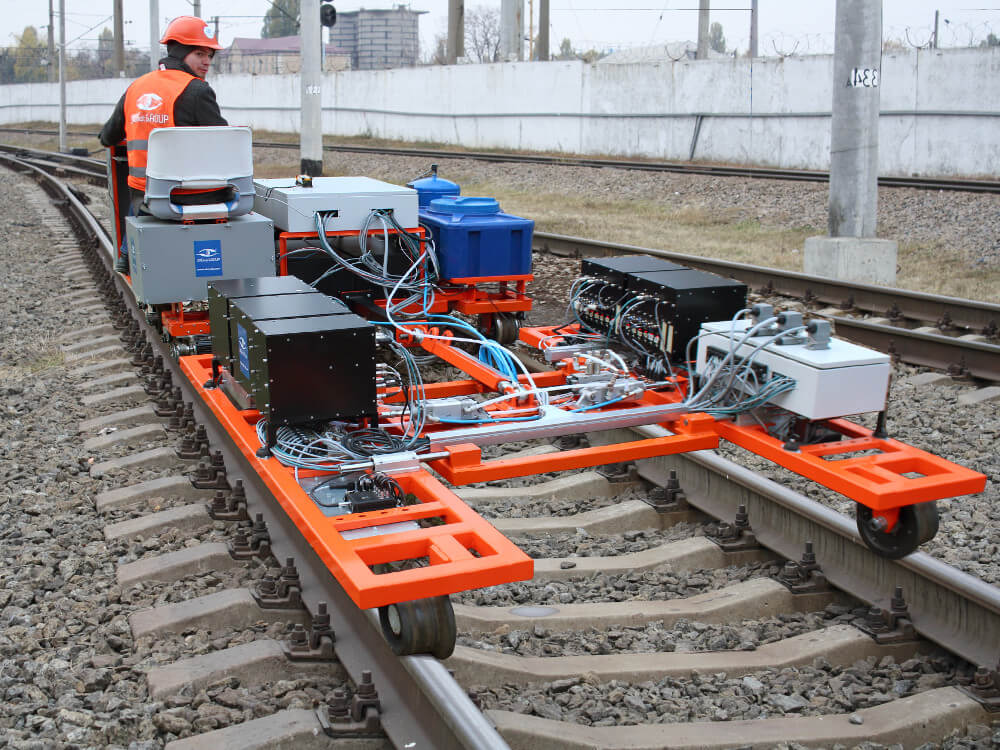

OKOSCAN 73HS High-Speed Rail Testing System

The OKOSCAN 73HS System is a cost-effective NDT solution for automated rail track inspection, which allows reliably locating all types of fatal defects, including transverse and longitudinal horizontal cracks, cracks originating from bolt holes, etc. The System operates at a speed of up to 40 km/h (25 miles).

The System consists of:

- a flaw detection trolley

- 4 wheel probes

- OKO-24 ultrasonic modules (24 pcs minimum)

- an encoder

- a PC with special-purpose application software.

Trolley (Carriage)

The inspection trolley carries the wheel probes ensuring their positioning and movement along the rail axis. The trolley automatically adjusts to the gauge type (track width).

Track inspection trolley advantages:

testing curves with a radius of less than 200 m (at a lower testing speed – of no less than 120 m);

prompt automatic gauge type adjustment;

easy maintenance;

controlling the suspension system (cant).

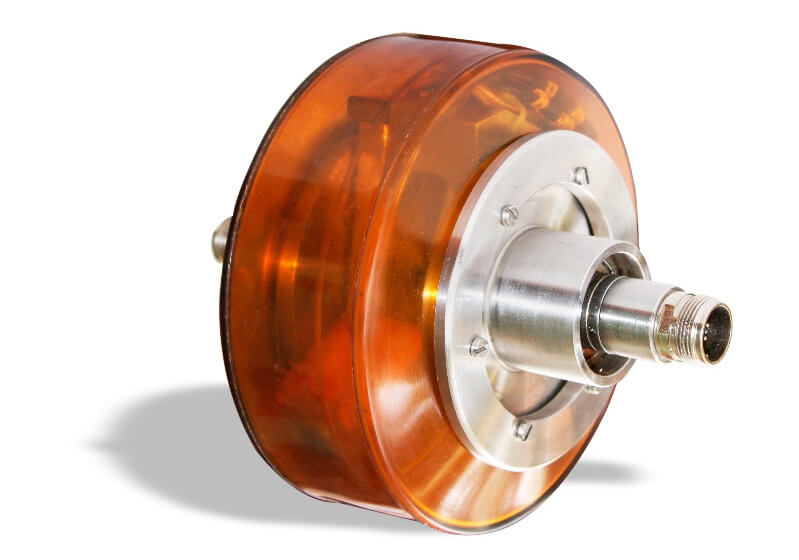

Wheel probes

The OKOSCAN 73HS System incorporates four (4) wheel probes, each comprising:

three 70-degree transducers, 2 MHz

one 45-degree transducer, 2 MHz

one 40-degree transducer, 2 MHz (Side looking)

one 0-degree transducer, 4 MHz

two 58-degree transducers, 2 MHz (Side looking).